The process of manufacturing insulating glass units (IGUs) is both intricate and fascinating, combining precision engineering with high-tech materials to create efficient, energy-saving windows. This article provides a detailed guide through each step of this process, emphasizing the importance of precision and efficiency. We will also delve into the crucial role of quality control, highlighting the Sparklike insulating gas measurement devices as a key factor in ensuring the integrity of the IGUs. Read our previous article Optimizing Quality Control Process of Insulating Glass Units.

Detailing the Step-by-Step Process of Insulating Glass Production

Material Preparation The first step in IGU manufacturing is preparing the raw materials. High-quality glass sheets are selected, and any coatings or films are applied. The type of glass and coatings used are critical as they determine the thermal and acoustic properties of the finished product.

Glass Cutting Precision is paramount in the cutting process. Glass sheets are cut to the required sizes using advanced cutting machinery. The accuracy of these cuts is crucial for the proper fitting of the IGU components.

Glass Edging After cutting, the glass edges are meticulously ground and polished. This step, known as glass edging, is crucial for safety, aesthetics, and ensuring a proper seal in the later stages. Edging removes any sharpness and flaws from the cut edges, which could affect the structural integrity of the IGU.

Glass Washing and Drying Post-edging, the glass sheets undergo thorough washing to remove any impurities. This step is vital to prevent any defects in the final product. The glass must be completely dry before assembly to avoid moisture getting trapped inside the IGU.

Spacer Assembly Spacers, which maintain the gap between the glass panes, are then installed. The size and material of the spacer contribute significantly to the insulating properties of the IGU.

Gas Filling Before sealing, the space between the glass panes is filled with an insulating gas, such as argon or krypton. This step is critical for enhancing the thermal performance of the IGU. The gas fill needs to be precise, as it significantly affects the unit’s insulating properties. Sparklike helps with assuring that the gas fill rate is proper and according to standards. Watch a video Pilkington Polska uses Sparklike Handheld to test argon to quality control thier insulating glass manufacturing process.

Understanding the Role of Machinery in Insulating Glass Assembly

Automated machinery plays a significant role in assembling IGUs. Machinery ensures consistent spacing between the glass panes, applies sealants accurately, and helps in aligning and pressing the panes together. This automation enhances efficiency and reduces the likelihood of human error.

Overview of Cutting, Edging, Washing, and Sealing Processes in Manufacturing

Precision Cutting and Edging Techniques The combination of precision cutting and edging ensures the right dimensions and safe, smooth edges, vital for the assembly and sealing processes.

Advanced Washing and Drying Systems These systems use specialized detergents and high-pressure water jets to cleanse the glass. The drying process usually involves heated air blown over the glass surface.

Gas Filling for Enhanced Insulation The insulating gas is filled into the unit, drastically improving its thermal efficiency.

Sealing for Insulation A primary and secondary sealant are applied to the edges of the glass panes, enclosing the spacer. These sealants are crucial for maintaining the structural integrity and insulating properties of the IGU.

The Role of Add-Ons in Insulating Glass Production

Add-ons in IGU production can include special coatings, additional glass layers, or gas fills. These add-ons enhance the performance of the IGU in terms of energy efficiency, sound insulation, and UV protection.

The Importance of Sparklike Insulating Gas Measurement Devices

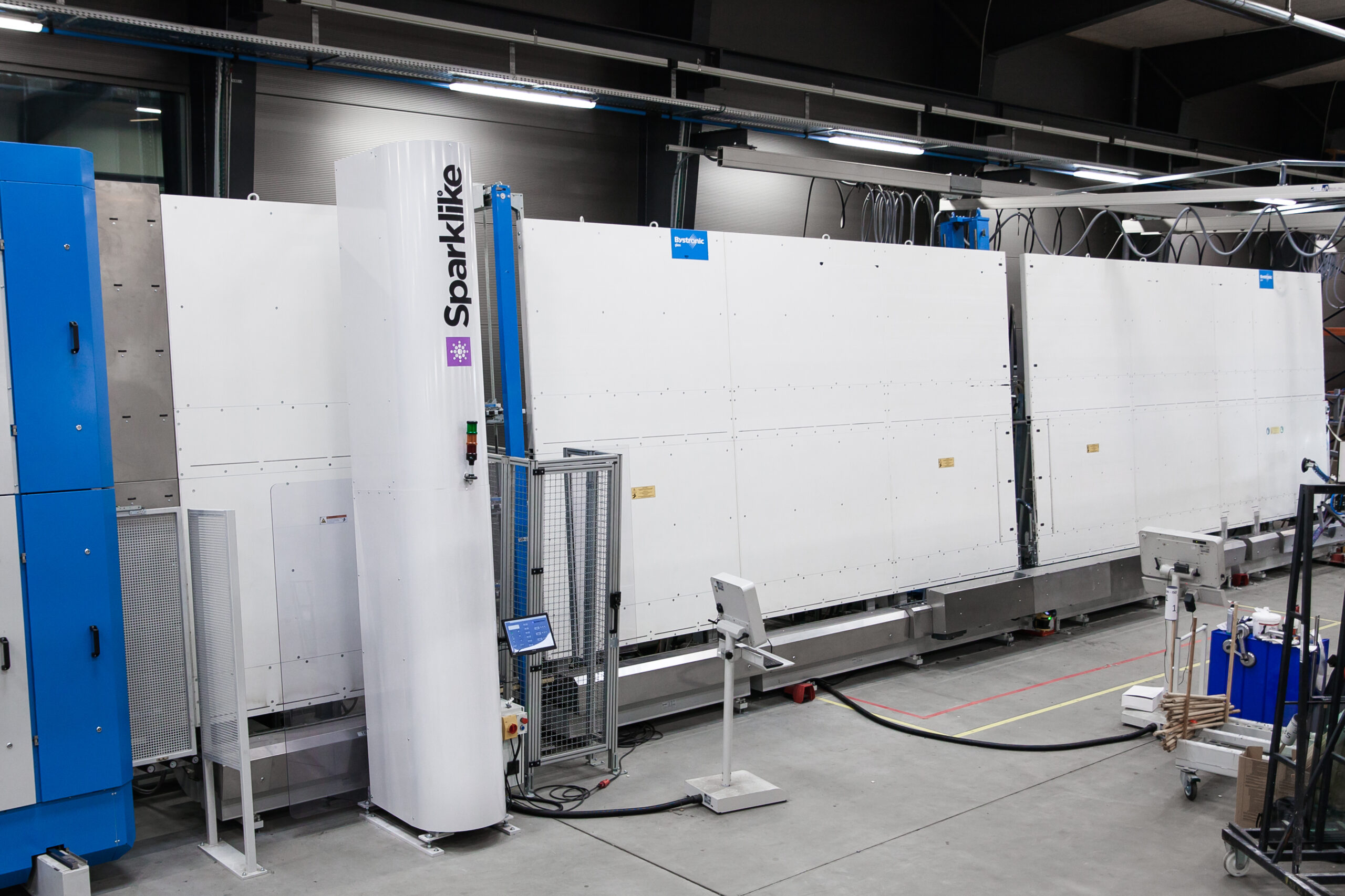

Quality control is a critical aspect of IGU manufacturing. Sparklike devices come into play here, offering non-invasive methods to measure the insulating gas fill levels in IGUs. Ensuring the correct gas concentration is crucial for the thermal properties of the IGU and acts as a proof that the gas press and sealant works properly. These devices enhance the reliability of the final product without compromising the unit’s integrity.

Sparklike devices:

- Sparklike Handheld™ – for double glazed insulating glass units

- Sparklike Laser Portable™ – for double and triple glazed insulating glass units with coatings and lamination

- Sparklike Laser Integrated™ insulating gas measurement station integrated to the IG-line – for double and triple glazed insulating glass units with coatings and lamination.

Conclusion

The manufacturing process of insulating glass is a sophisticated blend of precision, technology, and efficiency. From the careful preparation of materials to the detailed assembly and quality control, each step plays a vital role in producing high-quality IGUs. The integration of devices like Sparklike’s gas measurement tools further underscores the industry’s commitment to quality and innovation. Understanding these processes not only demystifies IGU production but also highlights the technological advancements in this field.