This text tells how to adjust the laser temperature of Sparklike Laser. If the parameters and the graph on the daily operations are incorrect, please try the following actions below. Also Please read the manual for Sparklike Laser Portable.

- Let the device warm up for 15 minutes

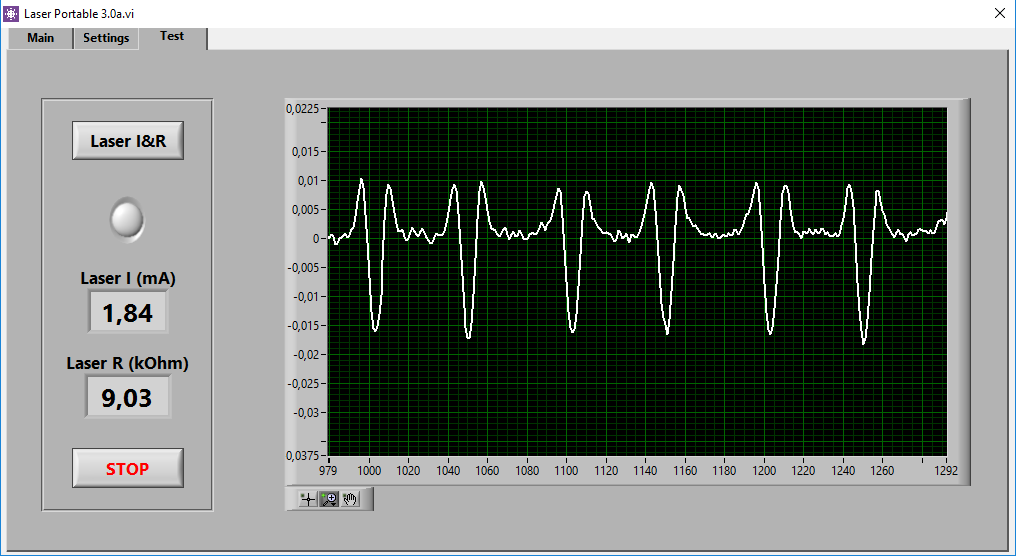

- Press the “Stop” button and then “Laser I&R” button on the Test page again to restart the test process (see picture). If the readings or the graph are still incorrect, restart the program (see Chapter 6.1. Restarting the program 2.1) and press “Laser I&R” button again. See picture A for reference.

- If this does not help, and the graph is still not correct (between 30-70 dots equal spacing), it means that the laser temperature is incorrect and needs to be adjusted: Try the self check function on Settings Page. You will have an info screen about laser temperature adjustment. See the picture Peaks equally for the reference.

If the temperature of the laser has changed so much that one cannot see the peaks in the Test page “Laser I&R” test, one can fine-tune the temperature as follows (Sparklike technical support can help with this).

- Open the c:\temp\Settings.ini file with Windows Notepad.

- Change the value of the “T_fine_tune” variable. Changing the value from 0 to 0,01 will move the peaks to about 5 data points. Using a negative value (-0,01) will move the peaks to the opposite direction.

- Save and close the file.

- Open the laser software and run the “Laser I&R” test from the “Test” page. The peaks should have moved according to the value set to the variable.

- Increase the value as much as needed and try to find a value where the peak spacing is close to around 50 data points.

- Check that the final “Laser R” value is close (inside couple of hundred Ohms) to the “Rvalue” mentioned in the “Settings.ini” -file. If not, there could be another oxygen peak closer to the original value but to the “other direction” (negative or positive adjustment value).

Instructions with pictures can be checked from the instruction manual.