U-value (also known as thermal transmittance) measures how well a window prevents heat from escaping. It indicates the rate of heat transfer through the window structure — the lower the U-value, the better the insulation. U-value plays a key role in a window’s energy efficiency rating and helps determine overall building performance in terms of heating and cooling demand.

Check NFRC label to see how they present this information.

How is gas concentration related to u-value?

In insulating glass units (IGUs), the space between the glass panes is often filled with a gas like argon or krypton. These gases have lower thermal conductivity than air, making them more effective at reducing heat transfer. When the cavity is properly filled with insulating gas, the overall U-value of the window is reduced, which is the desired outcome for energy-efficient design.

Why does gas fill rate matter?

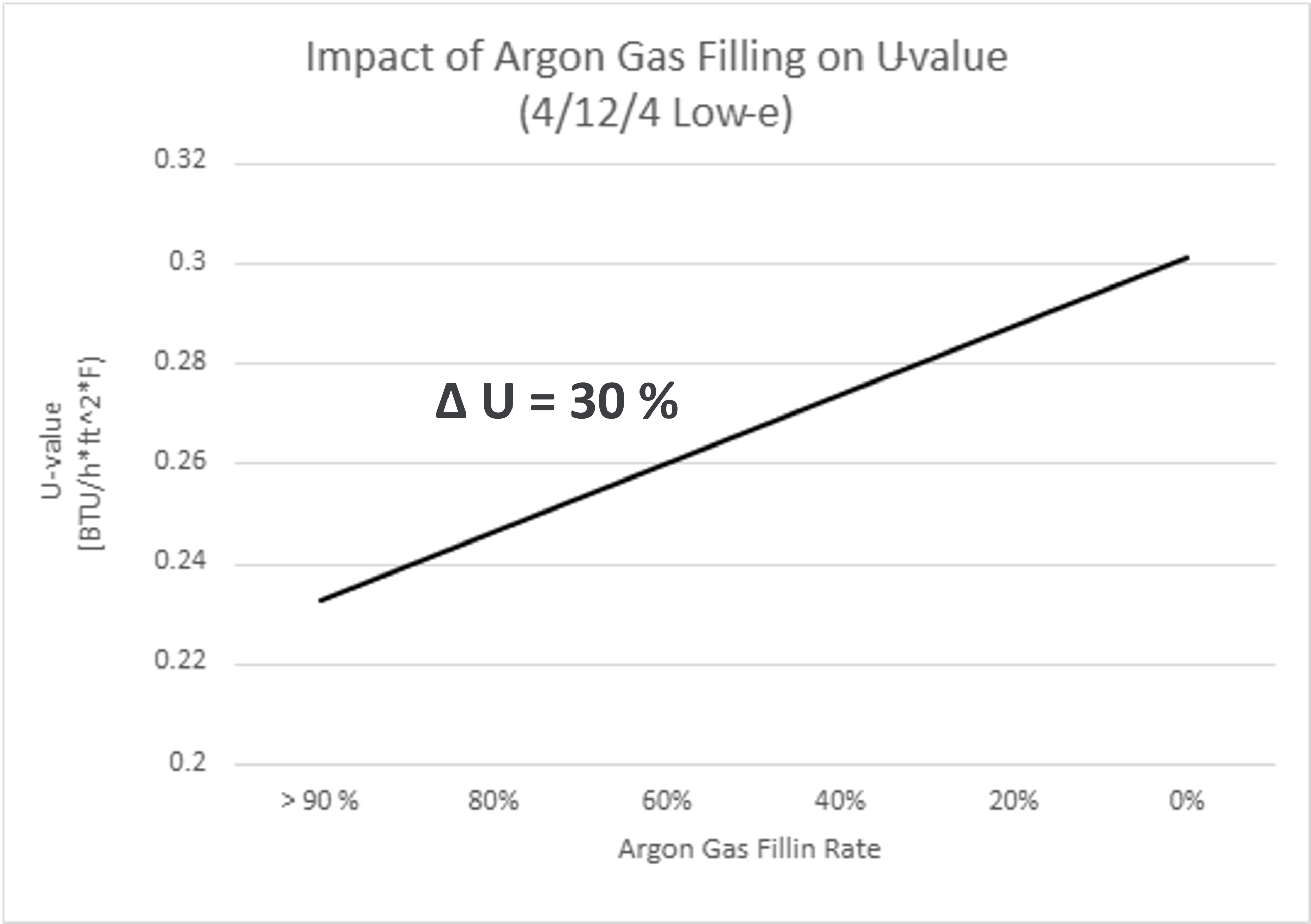

It’s not enough to simply add gas into the IGU — the fill rate (how much gas is actually present) directly impacts the performance. The chart below shows how a decrease in argon gas fill rate leads to a higher U-value:

In this example, a drop in fill rate from over 90% to 0% can cause the U-value to increase by up to 30%. Even a modest reduction below the optimal gas level can significantly reduce the thermal performance of the window.

There is an optimal concentration of insulating gas that maximizes the reduction in thermal conductivity. Beyond this optimal level, the additional benefit in terms of U-value reduction diminishes. Therefore, it’s essential to have the correct gas fill concentration by measuring gas level of IGUs to achieve the desired thermal performance. Read what is the optimal gas fill rate.

Measuring gas concentration ensures reliable insulation

Since the gas inside the unit is invisible, the only way to ensure proper gas fill — and therefore the expected U-value — is through accurate measurement. Measuring gas concentration during production or on-site helps:

- Verify quality

- Prevent costly performance losses

- Maintain compliance with energy-efficiency standards

Learn more in our blog: Why Fill Rate Matters for Reliable Insulation Performance