In the constantly evolving landscape of construction standards, it is essential for manufacturers, architects, and construction professionals to stay updated on the latest regulations. A critical standard in this regard within China is GB/T 11944, which pertains to insulating glass units (IGUs). This standard not only establishes the criteria for quality and performance but also specifically focuses on gas concentration measurement in IGUs, a significant aspect that we will explore in this article. Read also our articles on Standards and Regulations in Insulating Gas Measurement, National Construction Code (NCC) and ENERGY STAR® 7.0 requirement.

Gas Concentration: A Vital Element in Insulating Glass Units

Insulating glass units, consisting of multiple glass panes separated by a gas-filled hermetically sealed space, are known for their enhanced thermal insulation and soundproofing capabilities, surpassing traditional single-pane windows. The efficacy of these IGUs largely depends on the type and concentration of the gas within the sealed space. Typically, inert gases like argon or krypton are chosen over air due to their lower thermal conductivity. GB/T 11944 provides detailed guidelines for the measurement and maintenance of optimal gas concentration levels in IGUs, ensuring compliance with established thermal performance standards.

GB11944’s Protocol for Gas Concentration Measurement

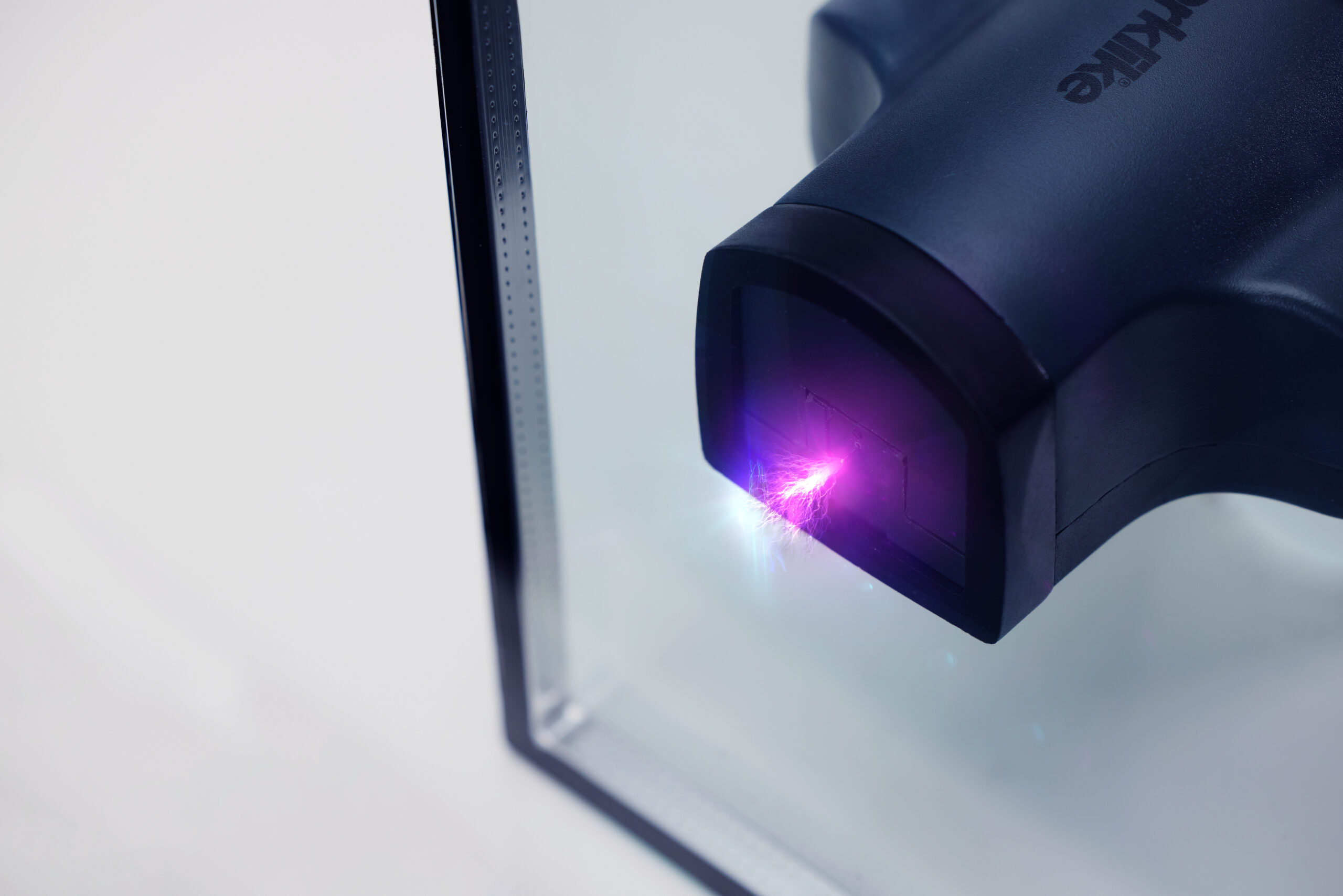

GB/T 11944 is a comprehensive standard covering the manufacturing, testing, and quality control of insulating glass in China. It includes specifics on dimensional tolerances, physical properties, and, crucially, gas concentration levels. The standard mandates precise analytical methods for determining the gas composition within the IGU cavity. This process involves extracting a gas sample from the sealed space and analyzing it with advanced instrumentation. GB/T 11944 specifies the procedures and protocols for gas sampling, analysis, and reporting to maintain accuracy and uniformity in the results.

Implications for Industry Stakeholders

For IGU manufacturers, adhering to GB/T 11944’s gas concentration guidelines is imperative. Precise measurement and control of gas concentration are not just about ensuring product quality; they are pivotal in determining the thermal efficiency and energy performance of the IGUs. Compliance with these standards boosts confidence in the product’s reliability and effectiveness, enhancing the manufacturer’s competitiveness and trust among consumers.

Architects, engineers, and construction professionals also benefit from the standard. By opting for IGUs compliant with GB/T 11944, they can guarantee the thermal efficiency and sustainability of building projects, thereby contributing to energy conservation and occupant comfort.

The Future of GB/T 11944 and Industry Innovations

As sustainability and energy efficiency become increasingly paramount in the construction sector, GB/T 11944 is likely to evolve, incorporating new advancements in gas concentration measurement technologies, like non-invasive spectroscopic methods or real-time monitoring systems. Stakeholders in the construction industry, by keeping pace with these changes and innovations, can drive meaningful progress and herald a new phase of high-performance building solutions.

In summary, gas concentration measurement is a pivotal component of the GB/T 11944 Chinese insulating glass standard, emblematic of the industry’s dedication to quality, performance, and environmental responsibility. Regular testing and adherence to these standards are essential for maintaining quality control in manufacturing and ensuring the advancement of IGU technology. By rigorously following these measurement protocols and embracing technological innovations, the industry can forge a path towards creating more energy-efficient and healthier built environments.