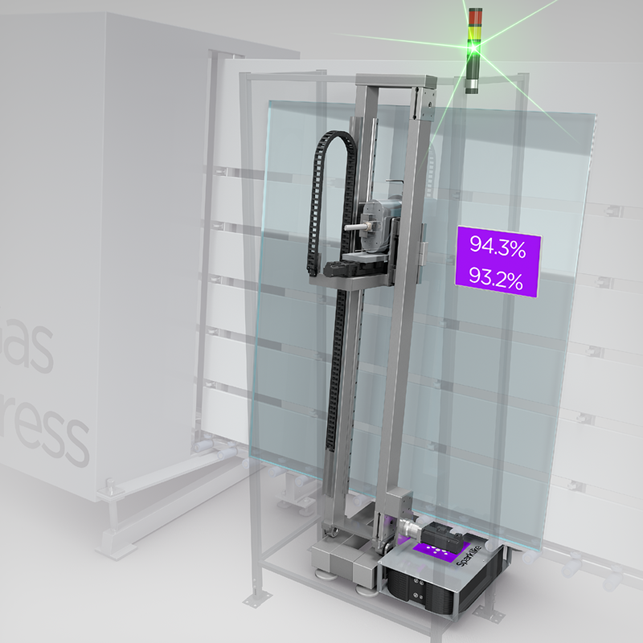

Until recently, there has been an important gap to be bridged between insulating glass production and comprehensive quality control to ensure that the IGU’s meet the prevailing standards and norms about u-value. Now that is possible with Sparklike Laser Integrated™ – IG-line integrated and non-destructive insulated glass equipment for argon measurement which enables to measure the quality of the produced insulating glass units – systematically and automatically.

100 % INSULATING GLASS QUALITY CONTROL STANDARD

Because of the increasing global competition and customers’ higher expectations for insulating glass performance, the industry is likely going to see a relatively rapid development towards 100% quality controlled and documented IGU’s. At the same time, as the reputation and continued operation are dependent on the quality and durability of the units produced, quality control is rightfully high on insulating glass manufactures’ priority. Especially, as competition is increasingly demanding manufacturers to yield towards longer product lifespan and warranties.

For the longest time, there has been an important commitment by most manufacturers to build insulating glass units which meet or exceed the current standards for finished IG units and their u-value. The sole hindrance being that, until recently, only a handful of IG manufacturers have had the insulated glass equipment in their disposal to control the argon concentration in an automated way. However, due to some never-before-seen advances in quality control and argon measurement technology, it has become possible to measure the argon concentration with an IG-line integrated non-destructive turnkey system. The measurement can be done for both, triple and double glazed IGU’s, even through coatings and laminated glasses.

IG-LINE INTEGRATED SYSTEM FOR ARGON MEASUREMENT

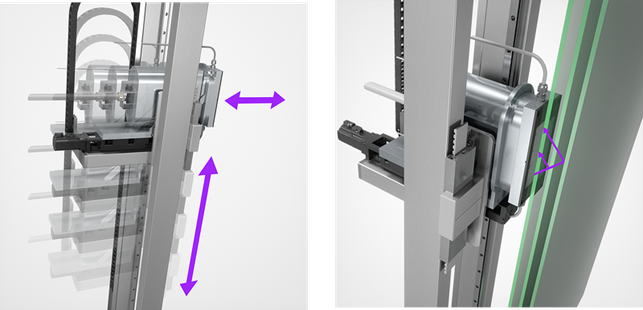

IG-manufacturers worldwide have now the possibility to control the proper functioning of the gas press in an automated way. Similar installations have already been realized with Sparklike Laser™ measuring components, but now everything is available ready-made, including installation, commissioning, and training. Furthermore, the measurement system’s dimensions and speed are compatible with all kinds of IG lines and the level of integration can be adapted based on the customer’s needs and product line requirements.